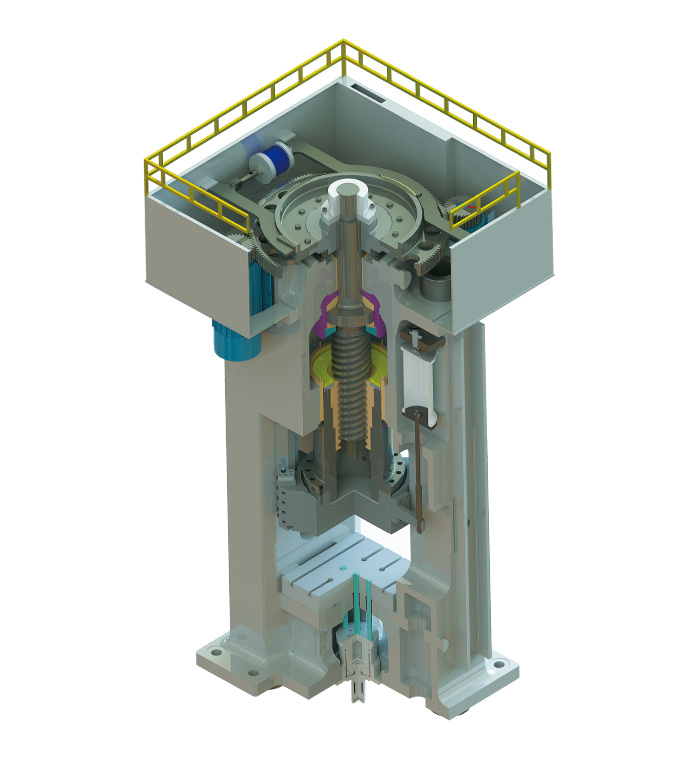

EP Series Electric Screw press

Category:Electric screw press

Introduction:

EP series electric screw press has the advantages of few parts, short transmission chain, simple structure, convenient operation and maintenance, stable running, low noise, etc:

Anti leaning load capacity is stronger, multi die forging capacity has more advantages;

Energy control is accurate, the product forming a good consistency;

Slide bottom dead center, not stuffy car;

Using the unique screw and flywheel connection structure;

High capacity of equipment, great fighting capacity;

The use of advanced lubrication technology, greatly extended the life of the screw pair;

Energy saving and environmental protection, the National Foundry and metalforming machinery quality supervision and inspection center, compared with the same specifications of double disc friction press, energy saving can reach more than 48.5%.

Anti leaning load capacity is stronger, multi die forging capacity has more advantages;

Energy control is accurate, the product forming a good consistency;

Slide bottom dead center, not stuffy car;

Using the unique screw and flywheel connection structure;

High capacity of equipment, great fighting capacity;

The use of advanced lubrication technology, greatly extended the life of the screw pair;

Energy saving and environmental protection, the National Foundry and metalforming machinery quality supervision and inspection center, compared with the same specifications of double disc friction press, energy saving can reach more than 48.5%.

Hotline:#

Details

Product parameters

| Main Parameters | Unit | EP-160 | EP-300 | EP-400A | EP-630A | EP-1000 | EP-1600 | EP-2500 | |

| Nominal Force | kN | 1600 | 3000 | 4000 | 6300 | 10000 | 16000 | 25000 | |

|

Allowing Load (Central Loading) |

kN | 2500 | 4800 | 6400 | 10000 | 16000 | 25000 | 40000 | |

| Moving Parts Energy | kJ | 10 | 26 | 40 | 90 | 150 | 280 | 500 | |

| Ram Stroke | mm | 300 | 400 | 410 | 500 | 550 | 650 | 700 | |

| No. of Stroke | min-1 | 30 | 27 | 24 | 21 | 17 | 15 | 14 | |

| Mini Die Height | mm | 380 | 400 | 480 | 600 | 700 | 800 | 1050 | |

|

Ram Bottom Dimension |

Front/Back | mm | 560 | 660 | 760 | 920 | 1030 | 1250 | 1450 |

| Left/Right | mm | 540 | 540 | 600 | 670 | 800 | 930 | 1250 | |

|

Table Dimension |

Front/Back | mm | 600 | 670 | 820 | 920 | 1000 | 1250 | 1450 |

| Left/Right | mm | 560 | 570 | 730 | 800 | 900 | 1100 | 1400 | |

| Table Bolster Height | mm | 120 | 120 | 120 | 180 | 180 | 200 | 280 | |

| Guide Strip Distance | mm | 545 | 545 | 640 | 707 | 810 | 940 | 1260 | |

|

Lower Ejecting |

Mode | Pneumatic | Pneumatic | Pneumatic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Force | kN | 50 | 55 | 60 | 150 | 150 | 200 | 400 | |

| Stroke | mm | 50 | 50 | 80 | 150 | 150 | 200 | 200 | |

|

Overall Dimension |

Front/Back | mm | 1700 | 1850 | 1910 | 2670 | 3000 | 3240 | 3890 |

| Left/Right | mm | 2800 | 2800 | 3490 | 2920 | 3560 | 4050 | 4175 | |

| Height | mm | 3730 | 4300 | 4500 | 5745 | 6395 | 6920 | 8535 | |

| Main Motor Power | kW | 22 | 45 | 55 | 110 | 132 | 2 x 132 | 2 x 220 | |

| Height above the Ground | mm | 3650 | 4600 | 4260 | 5245 | 5630 | 6015 | 7335 | |

| Main Parameters | Unit | EP-4000 | EP-6300 | EP-8000 | EP-10000 | EP-12500 | EP-16000 | |

| Nominal Force | kN | 40000 | 63000 | 80000 | 100000 | 125000 | 160000 | |

|

Allowing Load (Central Loading) |

kN | 64000 | 125000 | 128000 | 160000 | 200000 | 250000 | |

| Moving Parts Energy | kJ | 1000 | 1600 | 2300 | 4000 | 5000 | 7400 | |

| Ram Stroke | mm | 750 | 850 | 900 | 1000 | 1100 | 1200 | |

| No. of Stroke | min-1 | 11 | 8 | 8 | 6 | 5 | 5 | |

| Mini Die Height | mm | 1200 | 1300 | 1480 | 1700 | 1800 | 2000 | |

|

Ram Bottom Dimension |

Front/Back | mm | 2000 | 2100 | 2400 | 2800 | 2900 | 3000 |

| Left/Right | mm | 1330 | 1450 | 1800 | 2200 | 2300 | 2400 | |

|

Table Dimension |

Front/Back | mm | 2000 | 2150 | 2400 | 2800 | 2900 | 3000 |

| Left/Right | mm | 1600 | 1800 | 2100 | 2400 | 2500 | 2700 | |

| Table Bolster Height | mm | 300 | 320 | 350 | 350 | 400 | 400 | |

| Guide Strip Distance | mm | 1380 | 1620 | 1800 | 2240 | 2380 | 2500 | |

|

Lower Ejecting |

Mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Force | kN | 600 | 600 | 800 | 800 | 800 | 1000 | |

| Stroke | mm | 200 | 200 | 300 | 300 | 300 | 200 | |

|

Overall Dimension |

Front/Back | mm | 6600 | 7300 | 8000 | 8200 | 8300 | 8400 |

| Left/Right | mm | 9885/7385 | 7500 | 8300 | 9000 | 9600 | 9700 | |

| Height | mm | 9550 | 11500 | 13245 | 14000 | 16000 | 16500 | |

| Main Motor Power | kW | 2x315 | 3x315 | 4x315/2x630 | 6x315/3x630 | 6x350 | 4 x 630 | |

| Height above the Ground | mm | 8030 | 9300 | 10585 | 11500 | 13000 | 13500 | |